Built to Last. Trusted in the Field. Essential on the Line.

For power linemen, every tool matters – especially when it’s suspended thirty feet in the air and bearing the weight of critical equipment or materials. One of the most fundamental yet underrated tools in a lineman’s gear is the handline block. Whether you’re lifting tools, lowering materials, or ensuring a safe and efficient workflow, handline blocks are the workhorses that make it all possible.

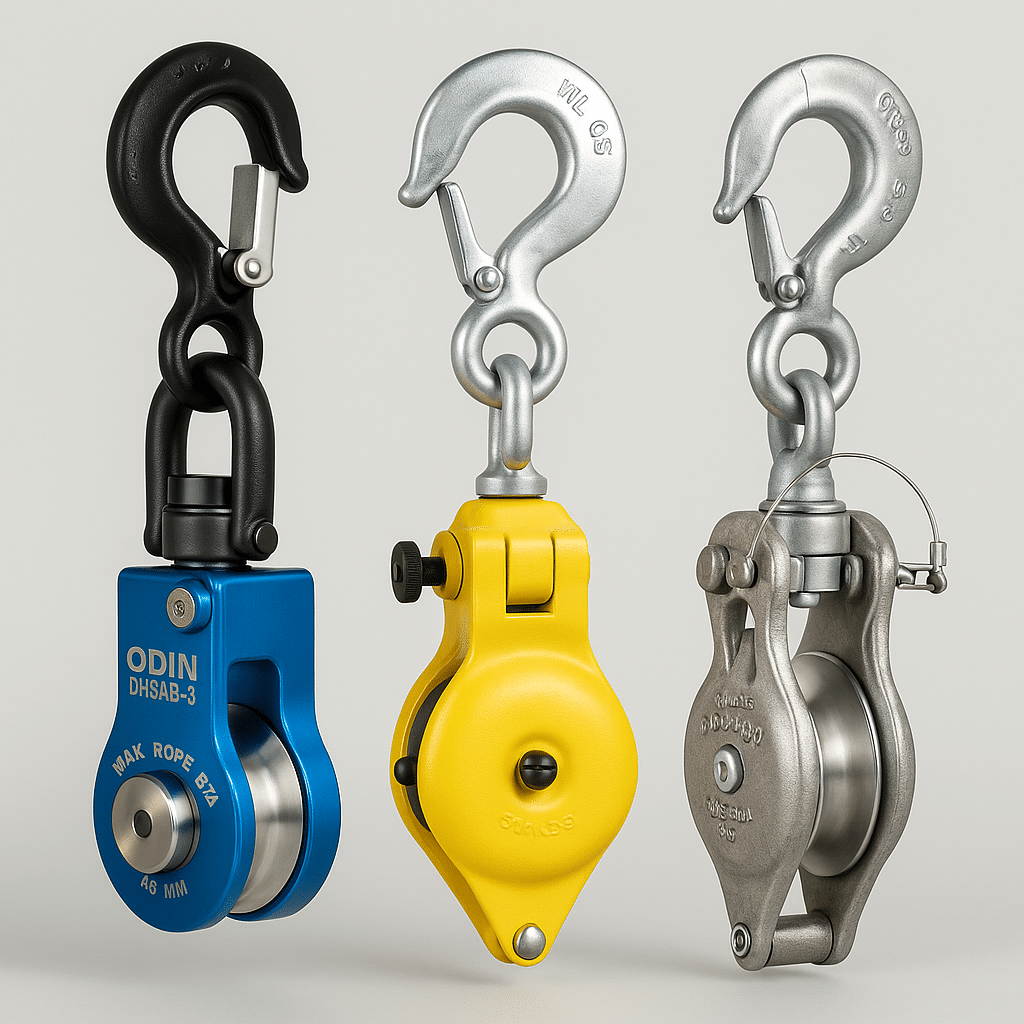

In this Tool Spotlight, we’re diving into three top-tier handline blocks from DDIN that are trusted across the industry for their durability, performance, and thoughtful design. Let’s break down what makes each block unique, and how to choose the right one for your crew.

1. 3″ Aluminum Gold Standard Handline Block

When you’re looking for peak performance from your gear, the 3″ Aluminum Gold Standard Handline Block lives up to its name. This block sets the industry benchmark for what a premium handline block should be. With a 3-inch aluminum sheave and a bronze bushing, this model is all about strength without sacrificing smooth operation.

Key Features:

- Working Load Limit (WLL): 1,500 lbs. with a 5:1 safety factor.

- Material: Precision-machined aircraft-grade aluminum with an anodized finish for enhanced corrosion resistance.

- Swivel Hook: Heavy-duty 360° swivel hook allows rotation under load.

- Swing Gate: Easy one-handed operation for quick rope loading.

- Rope Capacity: Accommodates synthetic rope up to 5/8″ in diameter.

- Compliance: Meets ASME B30.26-2015 standards.

This block is perfect for seasoned linemen who demand reliability and peak efficiency on every lift. It’s built for daily use and hard-hitting work without compromise.

2. Aluminum Handline Block

Sitting just below the “Gold Standard” in terms of price point but still boasting outstanding features, the Aluminum Handline Block offers rugged construction and excellent versatility. This model is a staple on job sites where reliability meets simplicity.

Key Features:

- Working Load Limit (WLL): 1,000 lbs. with a 5:1 safety factor.

- Material: Durable aluminum body with an open head design.

- Sheave: Smooth-running 3″ sheave accommodates rope up to 5/8″ in diameter.

- Retention: Open head retained with a ball detent pin for secure rope placement.

- Bearings: Shielded bearings packed with synthetic aviation grease for smooth operation.

Ideal for crews that need a dependable block without all the premium bells and whistles, this model offers outstanding everyday value. It’s especially well-suited for general line work, training yards, and utility crews looking to equip multiple team members.

3. Nylon Handline Block

Looking for a lightweight, cost-effective solution? The Nylon Handline Block gets the job done without sacrificing quality. While it doesn’t feature an aluminum frame, this block is still more than capable for many line applications and is a great choice for lighter-duty jobs or use in training programs.

Key Features:

- Working Load Limit (WLL): 1,000 lbs. with a 5:1 safety factor.

- Material: Lightweight nylon body with an open head design.

- Sheave: Smooth-running 3″ sheave accommodates rope up to 5/8″ in diameter.

- Retention: Open head retained with a ball detent pin for secure rope placement.

- Bearings: Shielded bearings packed with synthetic aviation grease for smooth operation.

The nylon model is also a favorite for newer linemen learning the ropes – literally. Its lighter weight makes it easier to maneuver and control, especially when climbing poles and adjusting loads.

Choosing the Right Block: Know Your Load, Conditions, and Crew

Each of these DDIN handline blocks serves a specific purpose on the line. The right choice comes down to understanding the needs of your job:

- High-duty, high-frequency lifts on busy job sites? Go for the Gold Standard for maximum durability and performance.

- Reliable daily use without premium pricing? The standard Aluminum Handline Block hits the sweet spot between cost and capability.

- Training, light-duty jobs, or backup gear? The Nylon Handline Block gives you functionality without the extra weight or price tag.

Handline blocks may not be the flashiest tools in a lineman’s kit, but they’re absolutely vital for safety, efficiency, and performance in the field. DDIN’s lineup of blocks, from the Gold Standard aluminum model to the rugged nylon variant, gives linemen the confidence to lift, pull, and lower with ease.

At the end of the day, the right handline block isn’t just about specs—it’s about trust. And when your job takes you 40 feet off the ground in all kinds of weather, trust is something you can’t compromise on.

Need help choosing the right gear for your crew? Reach out to your supplier or explore the full DDIN catalog for more high-performance line tools.